Wood-processing industries:

Prevent explosions and fires in wood chips and dust

Sawmills, furniture manufacturers, chipboard production and other wood-processing industries constantly work under the risk of fires and explosions in the unprocessed wood, wooden products, chips and dust.

The production processes are often violent and involve fast machinery and high drying temperatures, and the combustible wood materials continually come into contact with a range of ignition sources that may cause a fire or explosion in the blink of an eye, with potential serious consequences for the company, including:

- Serious injuries or fatalities among the employees

- Damage to machinery, transport systems and storage facilities

- Production interruptions

- Loss of income

- Expenses for repairs and replacement of damaged machinery

- Loss of customers

Ignition sources in wood-processing industries

Friction from machinery, foreign bodies or defective machinery are only a few of the ignition sources present in wood-processing industries. Spontaneous combustion in the materials due to compression, compaction or the gluing together of wooden chips and saw dust into chipboards are also familiar ignition sources in the wood-processing industries.

Particular danger zones in wood-processing facilities that should be protected include:

- Machinery such as planes, saws and belt polishers

- Filters

- Extraction/ventilation systems

- Chip silos

- Polishers

- Mills

- Dryers

- Presses

- Coolers

- Silos

- Sieves

- Sanders

- Conveyor belts

- Dosing bins

- Chippers

- Forming stations

Tailored fire protection for the wood-processing industries

At Nextech we have several years’ experience delivering fire protection systems to companies within various types of wood-processing industries, from sawmills and furniture manufacturers to manufacturers of chipboards and similar products. We offer you a tailored, experience-based fire protection solution that provides optimal protection in your facility.

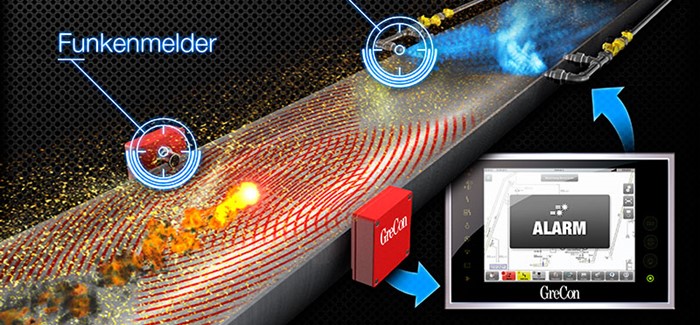

We always develop a thorough risk assessment mapping out all potential danger zones in the company and a subsequent fire safety proposal with indication of all the components – including spark detectors, infrared/thermographic monitoring, smoke detectors and spark and fire extinguishing components and diversion/interruption of material flow to remove sparks and embers from combustible materials – that will provide you with maximum safety in the facility concerned.

A fire protection solution from Nextech includes:

- A fast and reliable fire protection system tailored to your production

- Automatic detection and extinguishment of sparks, embers and other ignition sources – with minimal damage to your production

- Advanced, approved extinguishing measures for wood-processing industries

- Registration of all instances of sparks, embers or (too) high temperatures, ensuring easy identification and remedy of danger zones

Nextech offers to handle the completion of fire protection projects from idea to finished installation and subsequent service and maintenance.

Download brochures:

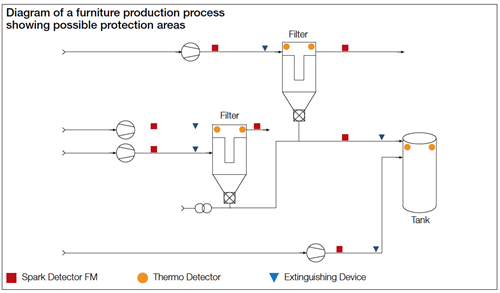

Fire and Explosion Protection for the Furniture Industry

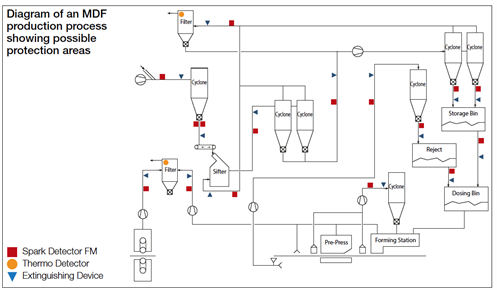

Fire and Explosion Protection of MDF Productions

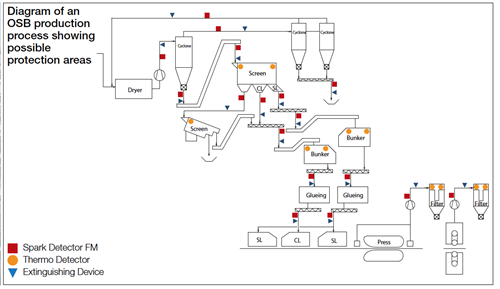

Fire and Explosion Protection of OSB Productions

Fire and Explosion Protection of Particleboard Productions

Fire and Explosion Protection of Plywood Productions

Read more about our services below:

- Project planning

- Sale of components for:

- Installation and initialisation

- Service and maintenance