Thermographic monitoring

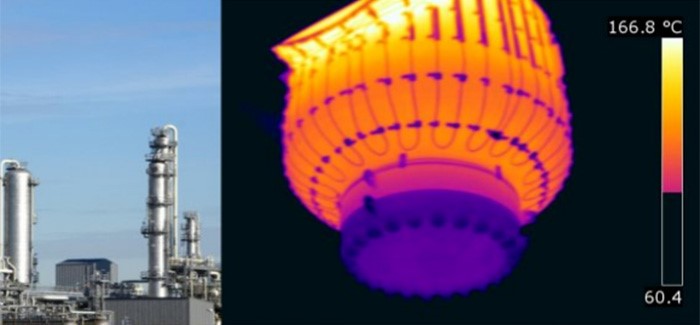

Optimise fire safety with thermographic monitoring by infrared cameras

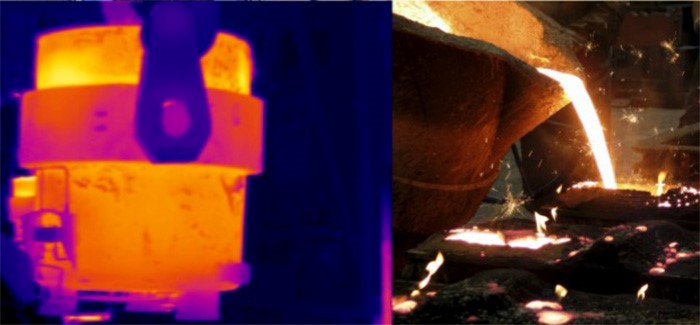

Fires and explosions in processing and production facilities may be caused by a number of ignition sources that are neither visible to the naked eye nor to traditional cameras. They are consequently hard to detect before the catastrophe has happened.

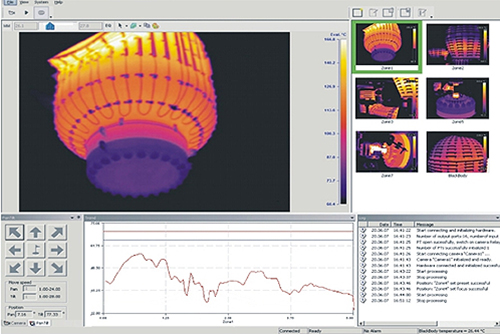

With thermographic monitoring through the IRMonitor system, temperature developments in high-risk areas of production processes, storage facilities and transport systems can be monitored around the clock, ensuring the automatic sounding of alarms or triggering of extinguishing measures if the temperature exceeds the permitted values.

IRMonitor gives you:

- Optimal monitoring through a tailored system of strategically placed cameras that are automatically monitored by the advanced IRMonitor software

- Automatic alarm or extinguishment in case of emergencies

- Numerous configurations and combinations of components, enabling tailored solutions to a wide range of industries

- Potential monitoring of large areas with a minimum number of cameras through pan/tilt monitoring that renders the cameras movable, enabling them to monitor larger areas than stationary cameras

- Potential monitoring in exposed environments through a range of specially developed camera enclosures, including ex protection that makes it possible to install the cameras in areas with the risk of explosions

Read more about IRMonitor: