Recycling:

Prevent fires during violent processing or in storage facilities

The processing of recycling materials is often a comprehensive and complex process that places great demands on the processing facilities. The original products – including tyres, plastic bottles, cardboard/paper or household appliances/electronics waste – must be taken apart, materials must be separated and treated correctly and safely, and the products often contain substances that may emit toxic smoke and constitute a hazard for both employees and neighbours in the area around the recycling plant in the event of fires.

Advanced fire protection is therefore crucial in order to ensure that ignition sources are detected and extinguished before they trigger a catastrophe. In the worst case, a fire in a recycling plant may lead to:

- Serious injuries or fatalities among the employees

- Injuries/poisonings in neighbouring areas

- Damage to machinery, transport systems and storage facilities

- Production interruptions

- Loss of income

- Expenses for repairs and replacement of damaged machinery

- Loss of customers

Ignition sources in recycling facilities

Recycling products often go through a necessary, rough processing on their way from product to reusable materials and by-products. This causes a number of potential ignition sources that in an instant may cause serious fires and explosions if they are not detected and stopped in time.

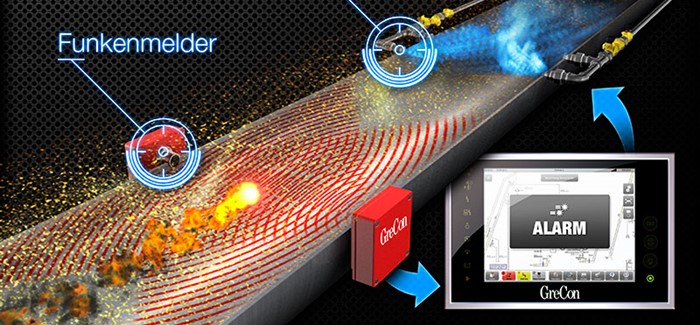

Foreign bodies getting stuck in machine parts or conveyor belts, defective machinery causing friction or high processing temperatures – all these may cause overheating, sparks or glowing embers that can rapidly ignite the combustible recycling materials.

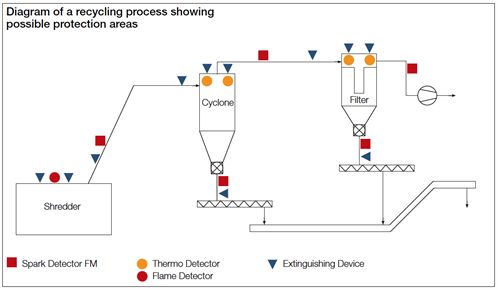

Particular danger zones in recycling plants that should be monitored and protected include:

- Granulators

- Sorting tables

- Wet and dry filters

- Cyclones

- Silos

- Mills

- Extraction systems

Maximise the fire protection of your recycling plant

With an advanced fire protection system from Nextech, the safety of recycling facilities can be optimised. Advanced detectors and extinguishing measures – including the world’s most advanced spark detection and extinguishing system from the German manufacturer GreCon – automatically detect and extinguish the far majority of ignition sources, preventing fires and explosions.

We initially compose a thorough risk assessment and subsequently a tailored safety measure proposal, mapping out the various danger zones in the facility. We offer a wide range of sensors, detectors and extinguishing systems and in each project compose a fire protection system tailored to the relevant risks in the facility in question.

A fire protection solution from Nextech includes:

- A fast, reliable fire protection system with all necessary components – tailored to each recycling plant

- The world’s most advanced spark extinguishing system with the world’s fastest extinguishing

- Extinguishing measures handpicked to fit the materials being processed and the work flows of the plant, ensuring optimal protection and minimal production interruption – among other things, our extinguishing measures include extinguishing by water, gas or diversion of material flow

- Exact registration of each case of embers or sparks, enabling easy identification of danger zones and the replacement or removal of defective machine parts or other causes of ignition sources.

Nextech offers to handle the completion of fire protection projects from idea to finished installation and subsequent service and maintenance.

Download brochure:

Fire and Explosion Protection of Recycling Plants

Read more about our services below:

- Project planning

- Sale of components for:

- Installation and initialisation

- Service and maintenance