Metal industry:

Safe processing even at high temperatures

High temperatures and sparks are unavoidable during the manufacturing processes of the metal industry, just as overheating and glowing embers may occur. Protecting the production plant against fires and explosions is crucial to prevent:

- Serious injuries or fatalities among the employees

- Damage to machinery, transport systems and storage facilities

- Production interruptions

- Loss of income

- Expenses for repairs and replacement of damaged machinery

- Loss of customers

Ignition sources in the metal industry

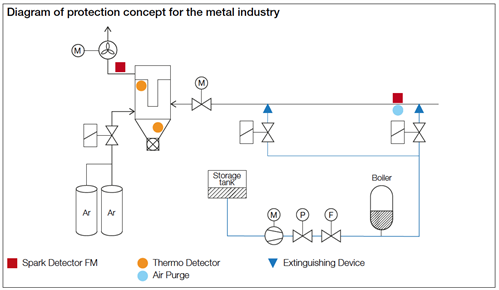

Potential ignition sources in the metal industry not only include the friction caused by foreign bodies or defective machinery or the sparks caused by welding and forging, but also the overheating of containers, transport facilities and other units where the scorching hot, melted metal is stored or transported. Fire protection of metal processing plants often requires a number of different types of sensors, detectors and extinguishing measures in order to cover all danger zones.

Particular danger zones in metal processing plants that need protection include:

- Filters at foundries or melters

- Chemical processes

- Ore shredders

- Welding processes

- Presses

- Extraction and ventilation systems

- Polishing processes

- Hardening shops

- Core removal

- Sand recycling

Tailored system gives maximum protection for the metal industry

At Nextech, we have several years’ experience within fire protection for the metal industry, and we sell some of the world’s most advanced fire protection systems. We always develop a thorough risk assessment mapping out all potential danger zones in the plant and a subsequent safety measure proposal indicating the components – including spark detectors, infrared/thermographic cameras, smoke detectors and spark and fire extinguishing components – that will give you maximum protection in the facility concerned. The components are chosen on the basis of the conditions of each danger zone, including light/darkness, dust level, temperature level and optimum extinguishing measure.

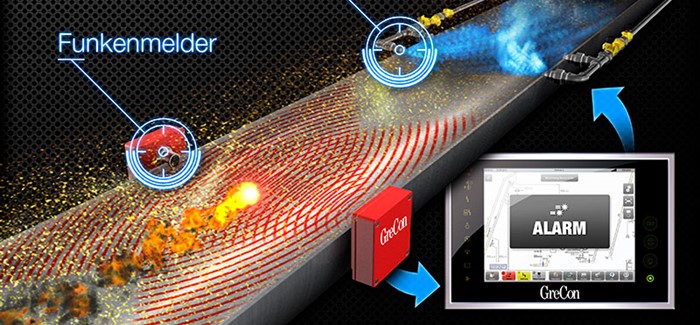

The system automatically detects and extinguishes ignition sources – among our products, we offer GreCon’s spark detection and extinguishing systems which in most cases eliminate 99% of all ignition sources before they develop into a fire or explosion, as well as advanced thermographic monitoring capable of identifying transport or storage units in danger of overheating.

A fire protection solution from Nextech includes:

- A fast, reliable fire protection system tailored to your production facility

- The world’s fastest spark detection and extinguishing system

- Fast extinguishment with targeted extinguishing measures (including gas, water or diversion of material flow)

- Access to manual triggering of extinguishment if needed

- Exact registration of each case of embers or sparks, enabling easy identification of danger zones and the replacement or removal of defective machine parts or other causes of ignition sources.

- Remote access to visual monitoring of areas with objects in risk of overheating

Nextech offers to handle the completion of fire protection projects from idea to finished installation and subsequent service and maintenance.

Download brochure:

Fire and Explosion Protection in the Metal Industry

Read more about our services below:

- Project planning

- Sale of components for:

- Installation and initialisation

- Service and maintenance