Food industry:

Safe production of dry and pulverised foodstuffs

Work within the food industry often includes the processing and handling of dry and pulverised raw materials and products such as sugar, cocoa, herbs, coffee and powdered milk. The processing and storage of these fine-grained and pulverised products constitute a large fire and explosion hazard. Even minor events may cause irreparable damage on an entire consignment of food products that have to be destroyed.

Reliable fire protection tailored to the challenges you as food producer are facing is crucial for the safety and dependability of your company. A fire or explosion may quickly become an expensive event and have serious consequences such as:

- Employee injuries or damages to production machinery

- Production interruptions

- Loss of large amounts of products that have to be destroyed due to smoke contamination

- Damage to buildings

- Loss of income

- Expenses for repairs and replacement of damaged machinery

- Loss of customers

Ignition sources in the food industry

Within food production there are a wide range of ignition sources during the production processes that the raw ingredients undergo before they are finished products ready for the customer’s shopping baskets. Foreign bodies, defective machinery, friction inside mills and grinders or high temperatures during processing are a few examples of the dangers.

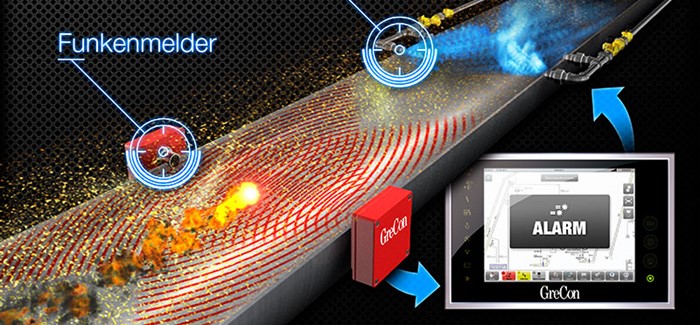

The finely ground and often dusty raw materials are highly combustible, and it often takes no more than a single spark to cause a dust explosion. It is therefore crucial to ensure that even the smallest sparks, embers or overheated objects are detected and extinguished within microseconds.

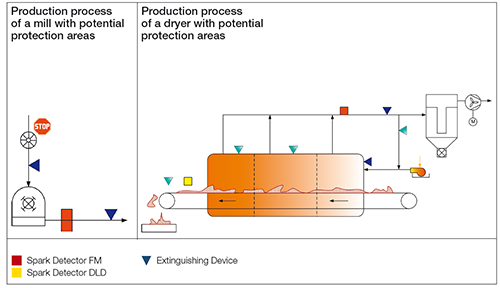

Particular danger zones in food-processing plants that should be protected include:

- Drying systems

- Silos

- Hammer mills

- Trundles

- Presses

- Sieves

- Transport systems

- Bucket elevators

- Cyclones

- Filters

- Extraction/ventilation systems

- Mixers

- Drums

Fire protection tailored to the food industry

At Nextech we have several years’ experience within fire protection of food processing facilities, and we can optimise the fire protection of any food processing plant. We sell some of the world’s most advanced and fastest fire detection, spark detection and spark extinguishing systems. The systems automatically monitor your production and storage facilities, detect sparks, embers and other ignition sources – and, most importantly, extinguish them before they can cause fires and explosions.

The systems are applicable in all types of food production and processing, and we tailor the system to each facility, the raw materials being processed and the types of extinguishment allowed – including gas, water or the diversion of material flows – that work optimally with minimal impact on the foods being produced. Our products furthermore include diversion gates, fire traps and shut-off gates in stainless steel for use in the food industries.

A fire protection solution from Nextech includes:

- A fast and reliable fire protection system tailored to your production facility

- Automatic detection and extinguishment of sparks, embers and other ignition sources – with minimal damage to your production

- Advanced, approved extinguishing measures for the food industry

- Registration of all instances of sparks, embers or (too) high temperatures, ensuring easy identification and remedy of danger zones

- Option of remote visual monitoring of zones with high temperatures through thermographic monitoring

Nextech offers to handle the completion of fire protection projects from idea to finished installation and subsequent service and maintenance.

Download brochure:

Fire and Explosion Protection for the Food Industry

Read more about our services below:

- Project planning

- Sale of components for:

- Installation and initialisation

- Service and maintenance