Biomass:

Prevent fires and explosions in biomass production

Biomass products play a major role in today’s electricity production. CHP plants depend on a continuous, reliable production without interruptions, enabling them to deliver their product – electricity and heat – to the consumers. The processing of the highly combustible biomass products includes a range of ignition sources that may cause fires or explosions with serious consequences. If an accident happens, the company is in danger of:

- Serious injuries or fatalities among the employees

- Damage to machinery, transport systems and storage facilities

- Production interruptions

- Loss of income

- Expenses for repairs and replacement of damaged machinery

- Loss of customers

Ignition sources in biomass production

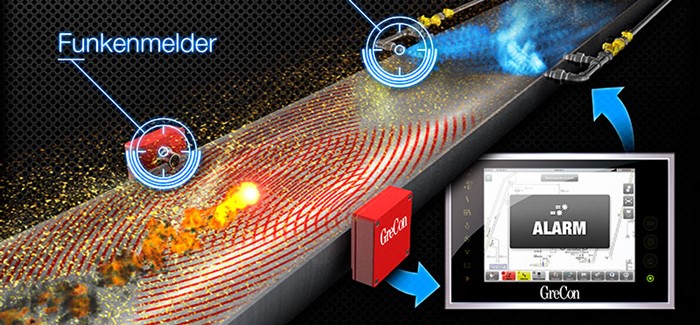

The road from fresh wood or other raw materials to finished biomass product – including wood pellets – goes through violent production processes such as crushing and grinding, drying and pressing. Sparks and embers from foreign bodies or defective machinery or spontaneous combustion or overheating can quickly set the materials on fire or cause dust explosions when sparks and embers travel through the system on conveyor belts or through ventilation shafts.

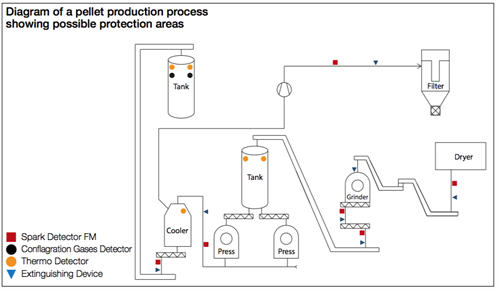

Particular danger zones in biomass production facilities that should be protected are:

- Hammer mills

- Silos

- Dryers

- Cooling towers

- Pellet presses

- Filters

- Ventilation/extraction systems

- Transport systems

Tailored fire protection for biomass production

Nextech offers a range of the world’s most advanced fire protection systems, which enables us to tailor an optimal solution for every industry we collaborate with. We begin every project with a thorough risk assessment of the production facility in question and subsequently develop a safety measure proposal indicating which components – including spark detection and extinguishing components, sensors, extinguishing measures and alarms – will give you optimal protection.

A fire protection solution from Nextech includes:

- A fast and reliable fire protection system tailored to your production

- Automatic detection and extinguishment of sparks, embers and other ignition sources – with minimal damage to your production

- Advanced, approved extinguishing measures for biomass production

- Registration of all instances of sparks, embers or (too) high temperatures, ensuring easy identification and remedy of danger zones

Nextech offers to handle the completion of fire protection projects from idea to finished installation and subsequent service and maintenance.

Download brochure:

Fire and Explosion Protection for the Pellet Industry

Read more about our services below:

- Project planning

- Sale of components for:

- Installation and initialisation

- Service and maintenance